A. Wendland GmbH

Everything from a single source. Since 2004.

Partner of system and component suppliers

We have been a respected partner to many system and component suppliers in the automotive industry for 20 years now, producing turned and cold-formed parts as well as assemblies and assembly parts. We have always distinguished ourselves through our breadth of production and our problem-solving expertise.

Strong in consulting

Our customers particularly appreciate the early advice and support in the inquiry phase. We see ourselves as a partner to our customers and are always looking for the most efficient and, above all, the most cost-effective way to manufacture your fasteners. Depending on your requirements and the factors “part geometry, tolerances and quantities”, we determine the appropriate manufacturing process. This saves you time and money. Take advantage of our expertise and the range of our production options for your procurement.

Stability and consistency

We ensure consistent results: in terms of quality and also in the overall process. Starting with smooth and fast communication, through the required quality standards and corresponding control measures, to standardized delivery processes.

Flexible and solution-oriented

Despite the consistency and stability of our processes, we always manage to demonstrate our flexibility. Whether it’s last-minute changes or urgent product availability: our customers appreciate our problem-solving expertise and reward this with loyalty.

Your series launch: in the best hands with us

We can usually respond to your request within 72 hours with a meaningful offer. And to ensure that series production can start smoothly after your approval, our team takes care of every detail: from A for order management to M for material validation and Z for drawing inspection. This saves time and ensures a quick start and stable throughput.

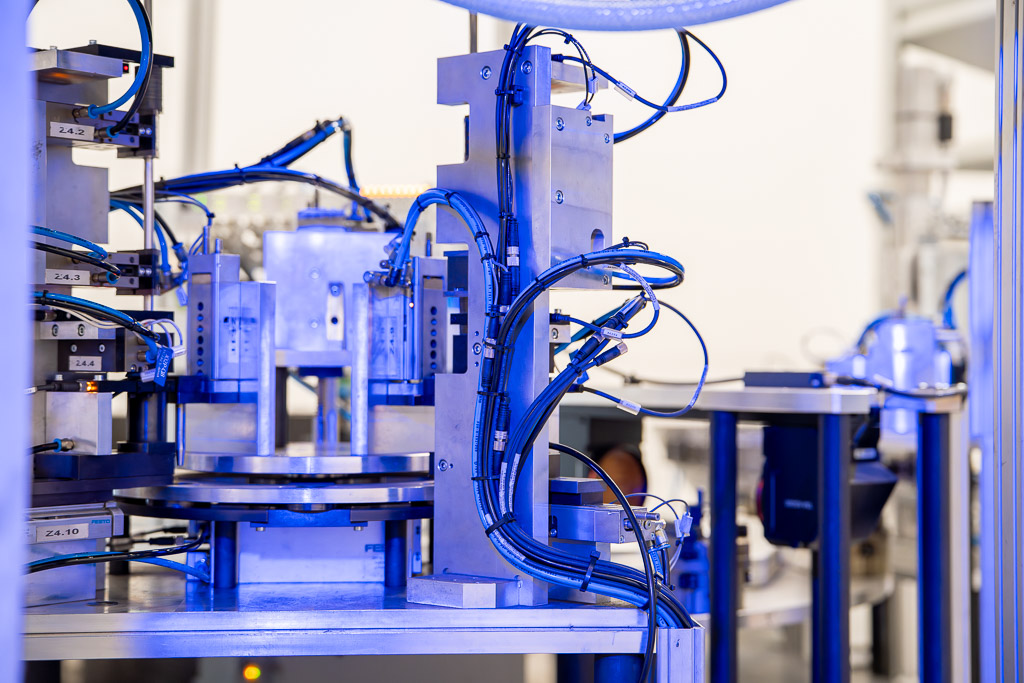

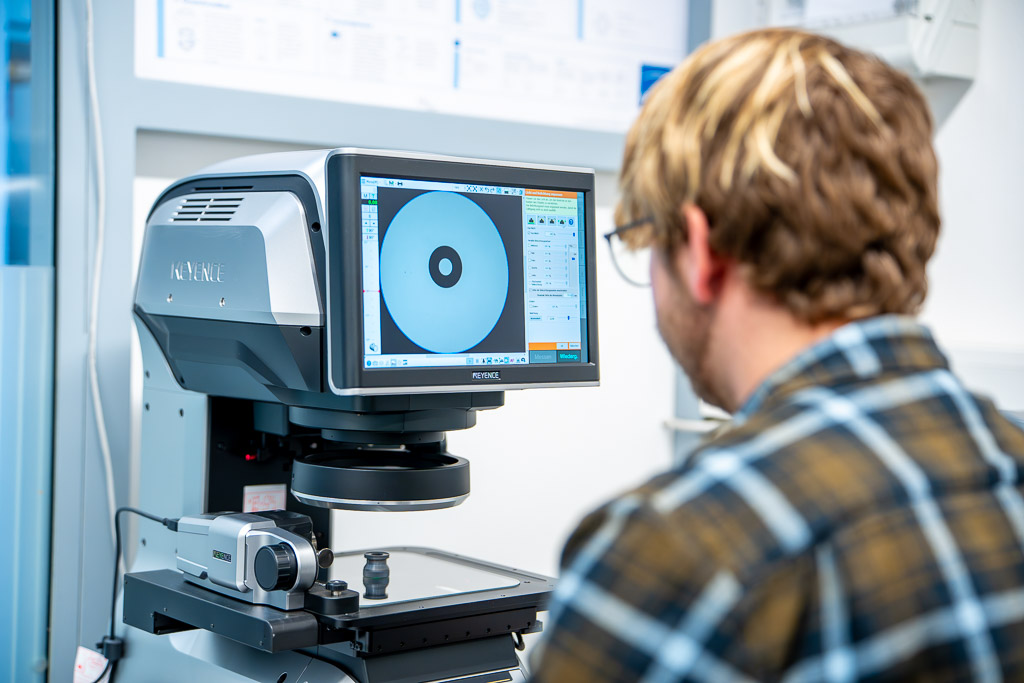

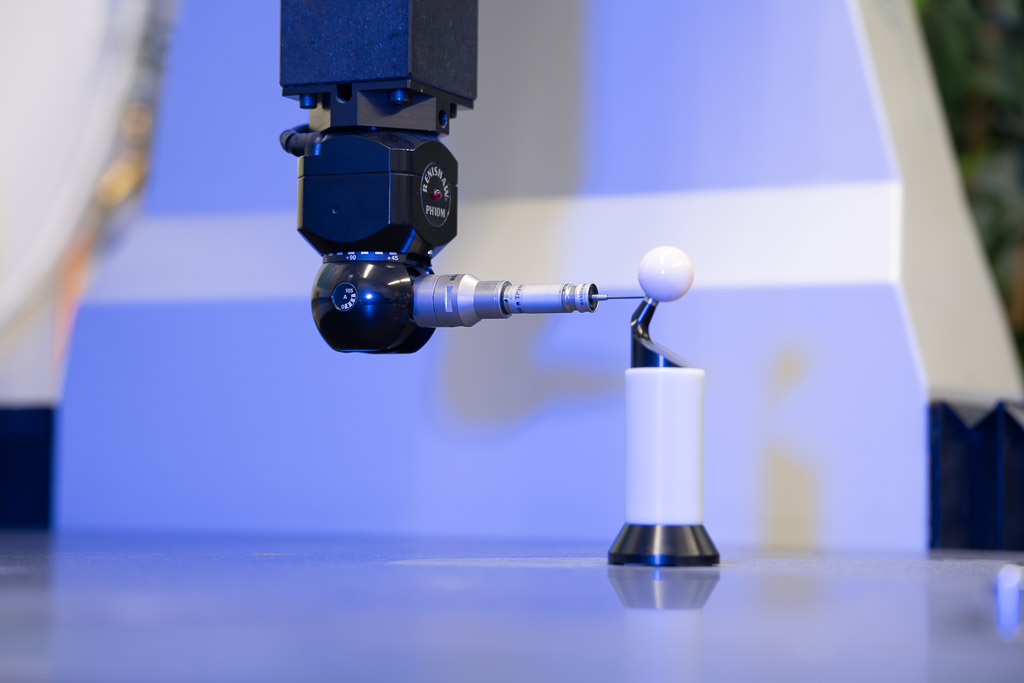

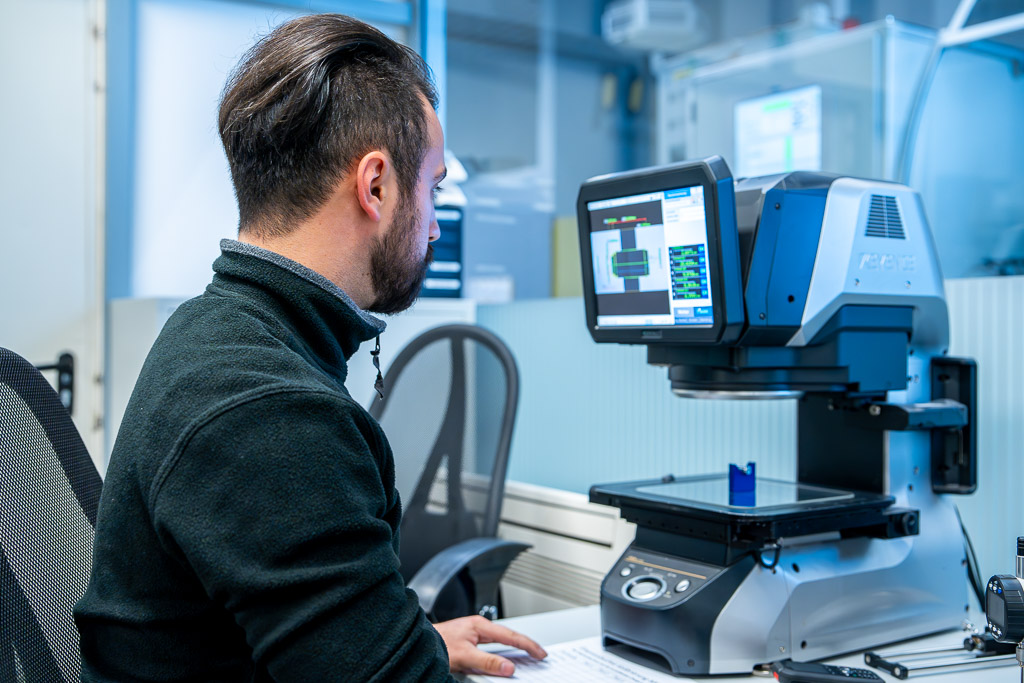

Quality: 0 % tolerance and 100 % control

Our machinery includes several fully automatic optoelectronic machines for 100% sorting. This ensures our 0-defect philosophy even with high quantities. No detail escapes the high-performance cameras, which guarantees seamless quality monitoring. Safety and predictability in series production: 0% tolerance, 100% control.

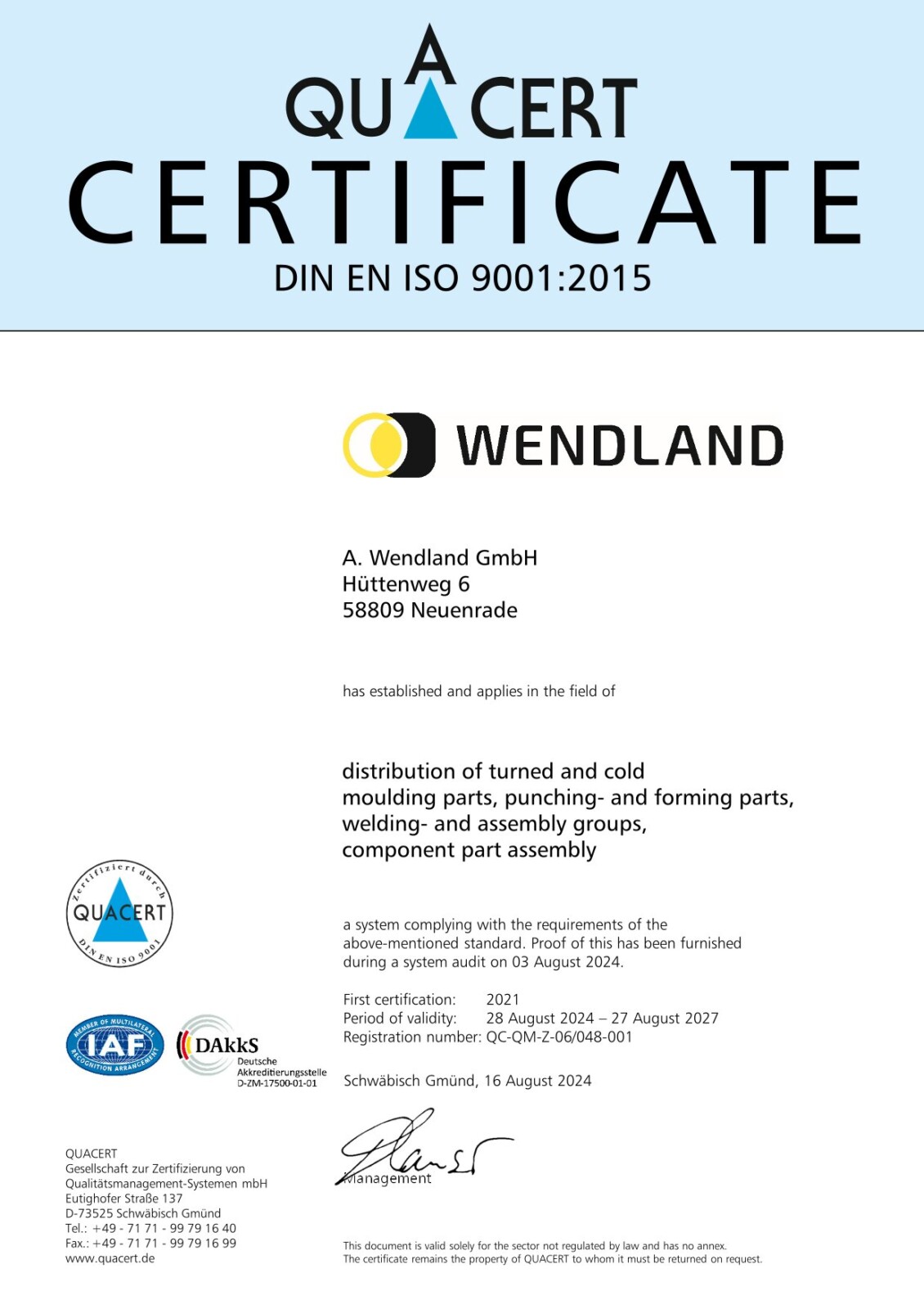

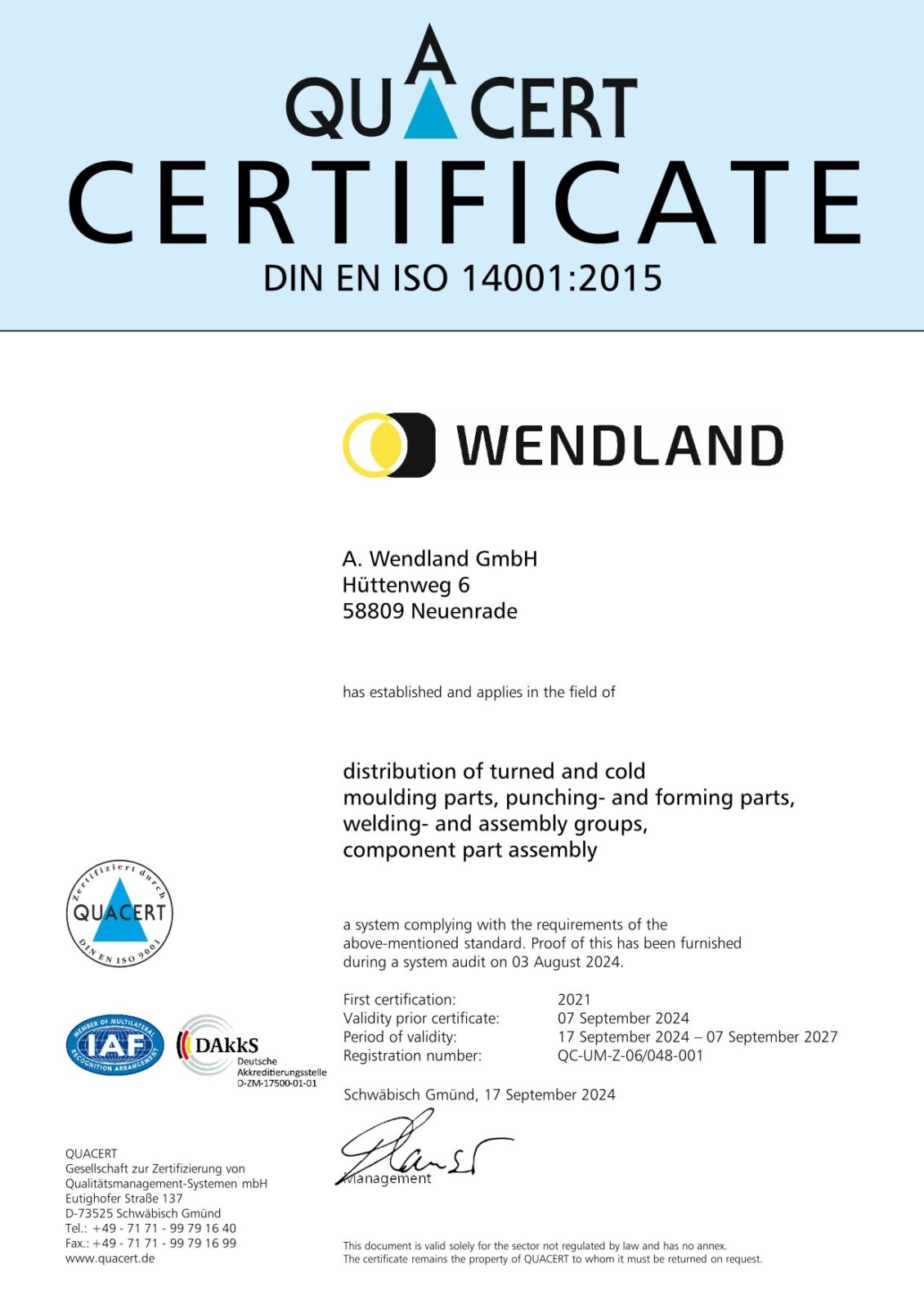

Excellent quality: certificates

Our ISO 9001 (quality management) and ISO 14001 (environmental management) certifications meet the industry standard. As we have already digitized the majority of our processes, we are currently preparing for TISAX certification for solid IT & data security management. Cyber attacks have already paralyzed many companies, which is why we want to continue to make our production secure and reliable for you. In this way, we are constantly increasing our reliability.